TRUMPF: Automated Welding Technology for Efficient Production

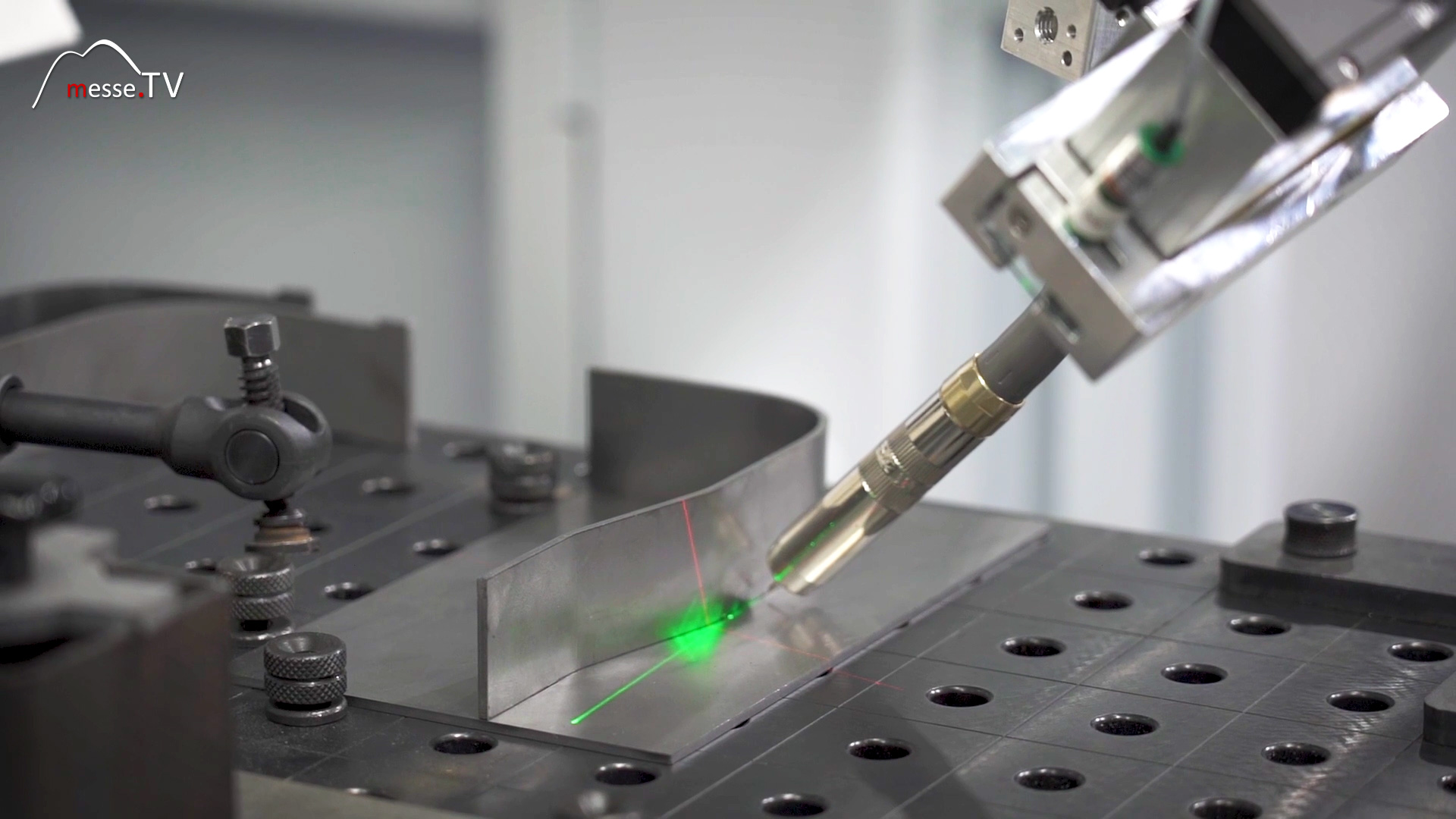

At Blechexpo 2023, TRUMPF can also proudly point to 1st place for its TRuArc Weld in the joining technology sector. Already part of the company's portfolio for several years, the TruArc Weld features a tracking sensor as a highlight. TRUMPF also received the Best Award for this, as the tracking sensor makes the system even simpler.

Welding technology system with minimal programming effort

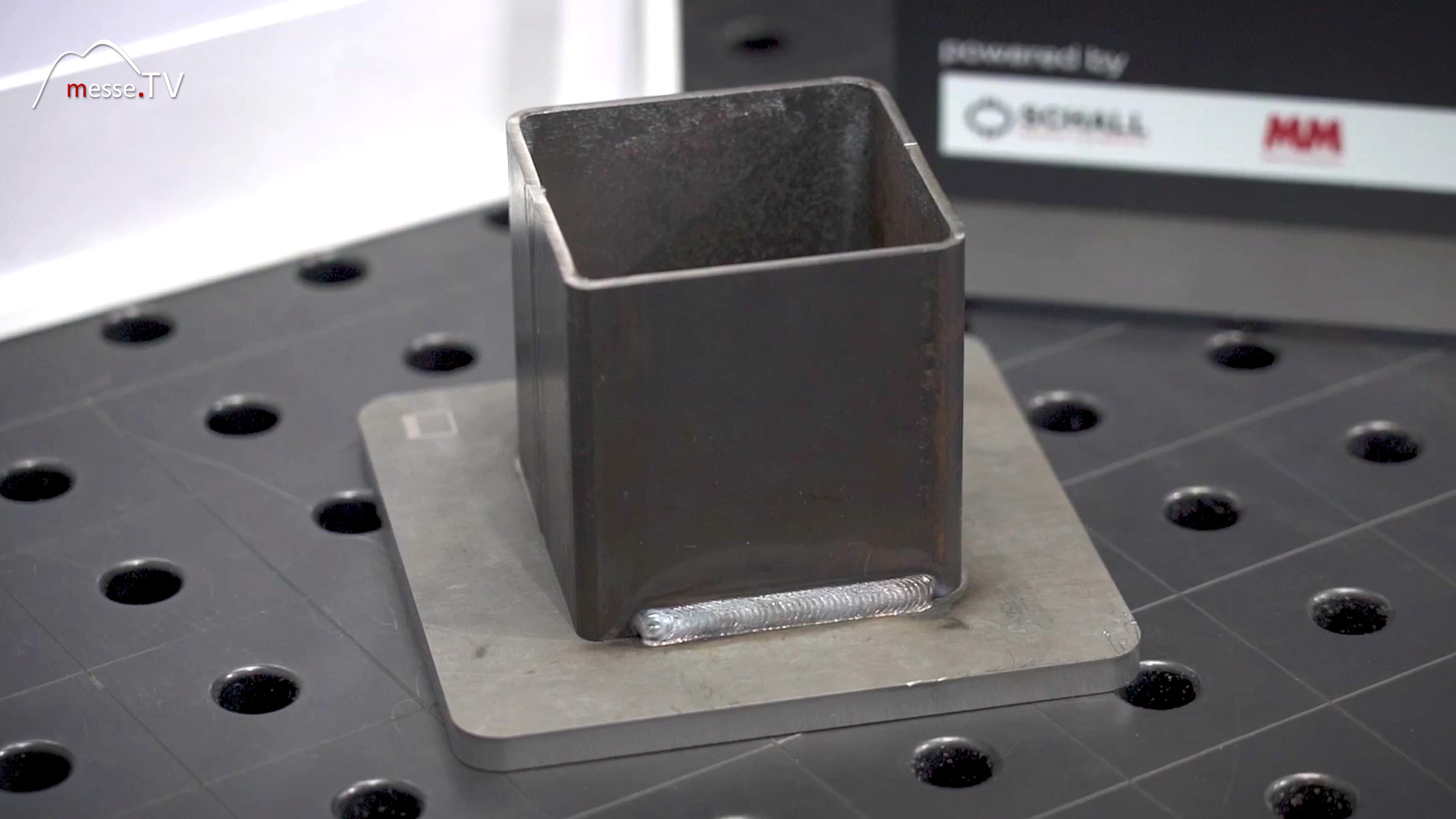

In the field of welding technology, too, a lack of young talent and qualified specialists is a major issue. With the system exhibited by TRUMPF at the trade fair, the programming effort can be reduced to a minimum. With the help of the tracking sensor, very good, high-quality components can be manufactured and programming can be massively simplified. The sensor is an arc process. If, for example, a flange needs to be programmed, the tracking sensor only needs the information about the start point and end point. The sensor then finds the seam position automatically, making programming easier. Fewer steps need to be carried out than with a conventional system.

Increasing production capacities despite a shortage of skilled workers

In discussions with customers, TRUMPF employees learn a lot about their customers' needs. The shortage of skilled workers is at the top of the list. Many people remember with horror the situation during the pandemic, when many welders from eastern countries were no longer able to travel to their workplaces in Germany. At that time, the new TRUMPF product that appeared on the market was a welcome help in terms of flexibility, as this system can relieve the welding shop and the resulting free capacity increases production. It is explicitly not about reducing the number of skilled workers, but about creating free capacity so that the company can react flexibly to customer inquiries.